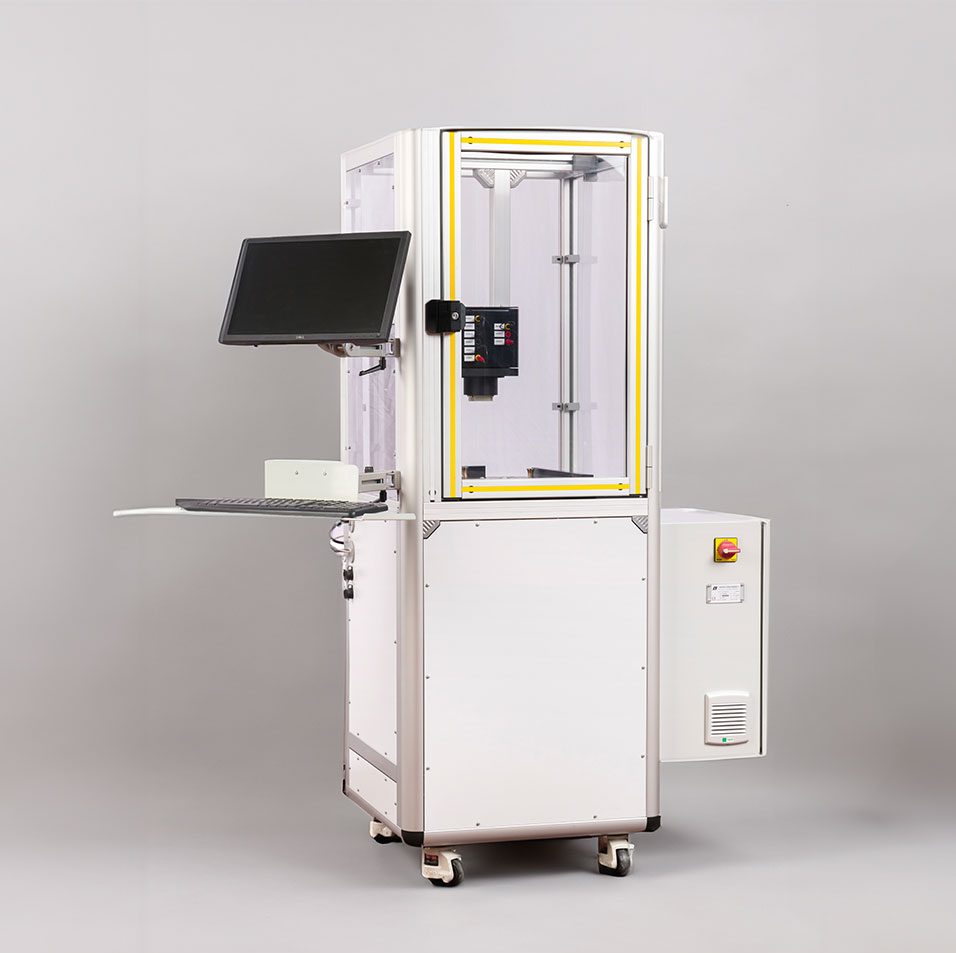

Ring coil system for Powertrain applications: measuring the stator cores

Electric motor performance is dependent on several parameters, including the magnetic characteristics of the stator. One of the major drawbacks in effectively predicting the motor behaviour is that the magnetic characteristics of the material are generally provided or measured not on the finished product, but on laminations before cutting or assembly, operations that can degrade or otherwise change their quality. With increased focus on efficiency of the electric motors, it is imperative that the magnetic property along with the losses associated with stator core are correctly and rapidly evaluated.

The classical method consists of simplifying the shape of the rotor as a ring and make manual measuring and excitation windings on it. This operation is time-consuming and can be done only in laboratory on selected products.

LE’s latest offering ‘Ring Coil’ eliminates the need of manual winding operation, allowing the operator to measure the stator magnetic characteristics 100% in line, during automated production.

The result from the software gives complete magnetic information of each stator and permits comparative and statistical analysis of the production.

KEY BENEFITS

• Automatic measurement of complete DC or AC hysteresis loop, normal magnetization curve, permeability curve

• The measuring cycle is fully automatic and is controlled by Laboratorio Elettrofisico exclusive software (Neon 2.0), resulting in complete characterization of the material under test

• Remanence Br, coercivity Hc, saturation values Hsat, Bsat, Jsat, cycle area, relative permeability, losses, losses separation, etc.

• International Standards: IEC 60404-4, IEC 60404-6, ASTM A596, ASTM A927

KEY BENEFITS

• Total quality control of the electric motors

• High efficiency, increase performance

• No more manual windings

• Reduce the time of measurements

• Safety because it is not necessary to handle large stators for winding

• No counting errors in the number of turns

• Multiple winding selection to optimize low/high frequency or level measurements